Mostly Toys and Flying Things

Friday, January 29, 2021

Friday, December 18, 2020

A Mysterious Zeppelin Bomber Discovered in Poland 100 Years After it Crashed

Crash Site of a Zeppelin Aircraft Found in Poland, a Century After it Happened

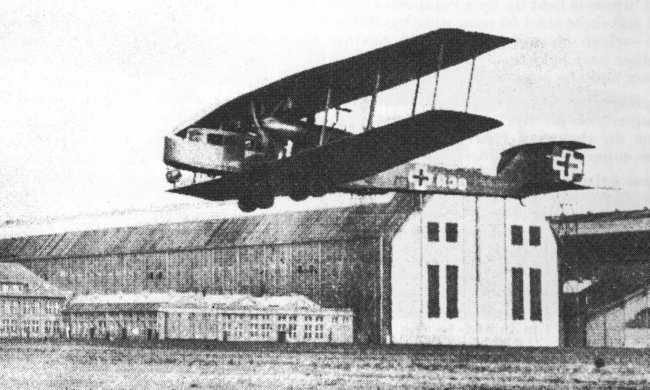

Over a century ago, the then young Western People’s Ukrainian Republic sent a Zeppelin Staaken aircraft on a secret mission. The plane was laden with valuables and carried two passengers apart from the crew. Mysteriously the aircraft crashed in Silesia in south-western Poland.

The Zeppelin crash has been described as the first air disaster to ever take place in Central Europe. The accident site remained shrouded in mystery until a group of explorers located the site of the crash near Racibórz.

This was a turbulent time in Central European history with Ukrainian nationalists fighting the Bolsheviks to create their own independent state, the Weimar Republic had grown from the German Reich, and Poland had declared its independence. This incited ethnic Polish separatists to begin agitating to have Silesia transferred from the Weimar Republic to Poland’s new nation.

On the 4th August 1919, the Zeppelin took off on its ill-fated flight from Breslau en route to Kamieniec Podolski in Ukraine.

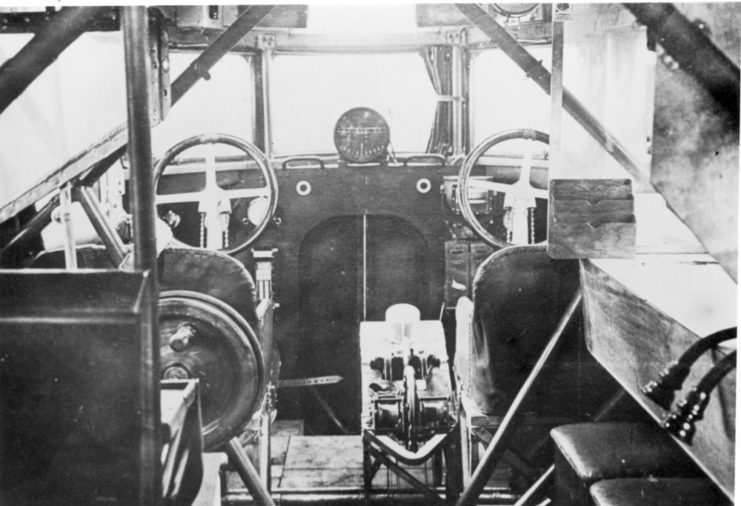

This Zeppelin was an enormous biplane, rivalling the World War II Flying Fortresses in size. It was a wooden bomber built during World War I by the Germans and was powered by five engines. This doomed flight was carrying gold and silver coins and banknotes specially printed in Germany for the Western Ukrainian People’s Republic’s newly proclaimed state. This treasure was vital for the new state to continue its fight for independence.

News reports from the time are confusing. One report claimed that locals heard an explosion and saw a pilot leap out of the cockpit, but he died when he crashed to the earth as his parachute failed to open.

Other reports claim the crew threw the chests of coins and the banknotes overboard in a desperate bid to lighten the aircraft and keep it in the air. This was to no avail, and the plane came down, killing all on board.

The cause of the accident was a mystery as all the crew were experienced airmen that had flown on bombing raids over France during World War I. One of the passengers on the plane was a Ukrainian officer, Dmytro Witowski, a Ukrainian Uprising commander.

One report suggested that the plane had been shot down by Silesian insurgents, but this theory was not proven.

The newly printed Ukrainian banknotes would have been of little value to anyone. Still, the gold and silver coins would have been an attractive goal for anyone, especially insurgents that needed money to maintain their fight.

The plane crashed in, what was then German territory, so German officials arrived at the site and collected the bodies and parts of the aircraft that remained.

As the years went past, the forest slowly reclaimed the crash site, and its location faded from memory. Trees grew, and their roots broke up the last of the plane that lay on the ground.

It seemed that the crash would be relegated to a historical tale until a local historian Henryk Postawka published some articles in the local press stating that he was sure of the location of the crash.

These articles attracted the attention of the Silesian Exploration Group. In an interview with TFN, Piotr Konarski said that using the reports and other research narrowed the area down to about 70 hectares.

Undertaking a search, they slowly narrowed down the search area until they found some melted aluminum on the top of a small hill. This was the first indication that they were in the right place.

Next to turn up was a button with Cyrillic lettering on it. The searchers feel sure this belonged to one of the passengers. In short order after that, they found plates from an oil tank and a compass. On one of the plates, there was an inscription, “‘Zeppelin-Werke G.m.b.H. Staaken,” a definite pointer showing the group had found the crash site of the Zeppelin.

They may have found the crash site, but many of the original questions remain. Why did the plane crash? Where is the treasure that was on board?